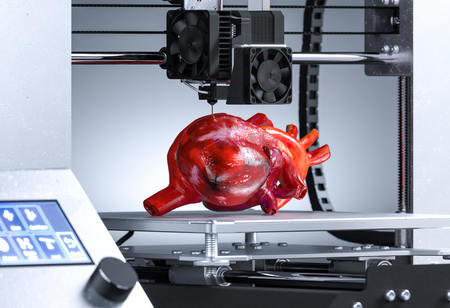

3D Printing Role in Upgrading Healthcare Sector

The unstoppable potential of 3D printing is totally altering the limitation of medical science. The latest and the most surprising invention in the healthcare sector is the spherical artificial eye with a 3D retina. This artificial 3D eye is said to have the potential to give vision to humanoid robots as well as comes as a new hope for visually impaired people. However, the function of the artificial eyes involves an electrochemical process that could be utilized from a type of solar cell.

3D printing has pushed the limits of the healthcare sector, by producing prosthetics human organs or body parts using fabricated human tissue that fit accurately. The ultimate benefits of using 3D printing in medical science include:

Personalized: Human anatomy differs from person to person, be it the sibling or even the identical twins no two individuals have the organs or body part of the same dimension or structure. Thus, 3D printing comes as a blessing in disguise by aiding in developing the customized fabrication of different types of tissues for recreating the needed organs or body parts.

Efficient: Developing a prototype usually takes a long time, however, through 3D printing making a prosthetic or an implant could be completed automatically just placing the accurate reading taken for the implants. With 3D printing, the output could be obtained quickly and are also quite reliable.

Cheaper: 3D printing is pretty cheaper when produced on large scale however, a small scale is not that affordable with 3D printing. Although, smaller produces could be now tested and developed as per the customer needs and are inexpensive as the cost of human resources is totally eliminated.

Considering its benefits and usage, 3D printing is widely adopted in healthcare thus, its market is estimated to grow from $0.84 billion in 2017 to $1.88 billion by 2022, at a CAGR of 17.5 percent. The plastic material used in 3D printing in healthcare is anticipated to rise at an impressive rate and it is expected that the total plastics shipped for medical printing purposes may exceed 570 tons in 2020.

Usage of 3D Printing in Regenerative Medicine

Regenerative medicine involves a lot of many arenas that use scaffolds, biomaterials, cells, or a combination of biomaterials and cells to create an organ for transplantation unlike the present scenario of depending on the donor model. Lately, the creation of multi-layered organs using soft biomaterials such as biomimetic synthetic polymers and living cell that has been the most challenging technological advancement in the field.

Usage of 3D Printing in Precision Medicine

This technology offers numerous opportunities for the development and preparation of personalized medicines at both the industrial scale as well as pharmacies. Thus, the invasion of 3D printing in hospitals and pharmacies are certainly enabling the doctors, nurses and the physicians to prepare a dose and delivery system based on the patient’s body condition and their physical requirement that depend on the patient’s age, lifestyle and gender. This way the medicines would be personalized according to the patient's requirements.

3D printing Organizes Research and Development Processes

Presently, the R&D sector is undergoing a crisis in the pharmaceutical industry, as the drugs tend to fail in the last stage of research. The bioprinted tissues are already put in use to increase the success rate of clinical trials. This not only reduces the damage caused to animals but also expedites the entire R&D process.