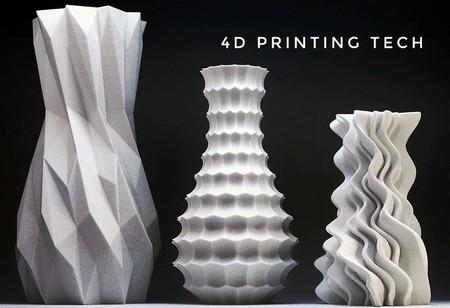

4D Printing the Shape-Morphing Tech that Can Revolutionize Industries

It’s a fact that in today’s world, technology is playing an important part in our lives and having a huge impact on how we do our daily day activities. Another fact is that we are living in such an era, where everything is temporary & ever-changing, especially technologies, that are getting evolved day-by-day. One such technology is - Printing technology. Though, 3D printing technology has existed for almost 30+ years now. Yet, as the additive manufacturing industry is discovering new applications, new materials, and new 3D printers, another technology is arising, called as the 4D Printing technology and it is coming straight from the future.

Right now the 4D printing technology is just in the nascent stage. While still in its early phases, technology has shown huge potential to transform organizations with customized and adaptive solutions for various challenges. 4D printing does not involve travelling in the fourth dimension of time, unfortunately, at least not yet, but it implicates the engineering of a new type of structure that can remember its original shape. The technology can be used in various domains and if leveraged meticulously, it can revolutionize the industry. Let’s have a look at its usage across the industries.

Building & Piping Industry

4D printing technology can revolutionize the piping industry by making self-repair piping system possible. Yes, one of the potential application of 4D printing would be pipes of a plumbing system that dynamically changes their diameter in response to the flow rate and water demand. Pipes that could possibly repair or change their structure themselves automatically if they crack or break, due to their ability to change in response to the environment’s change. This would avoid digging them up and changing them, which is not just a time-consuming herculean task but is a very costly process as well.

Furniture Industry

The furnishing products industry demands customization, and 4D printing is more than interesting for all applications that require a high degree of customization since it is possible to program the material according to our needs. At this stage, the concept might seem strange but you could imagine clothes that take the real shape of our body, furniture that folds and unfolds to save space, and more. As we know that the 3D printing in the furniture segment is limited by the size of the printer, 4D printing could allow to just print a flat board that will curl up into a chair or table by just adding water or light to it.

Medical Industry

The 4D printed healthcare applications may be the closest to commercial applications. The potential of this technology is extremely high for the medical industry, as the shape-shifting materials could be used for small, implantable medical devices. 4D printed proteins could be a great application. Another special material researchers are working on is self-folding protein. Not just that but tiny and soft devices crafted using the 4D tech could be inserted or implanted in people, and harden when they reach the affected area. But with a few possible exceptions, the wide-scale application remains years away. Most activity now is still in research and development. The market is in its infancy.

Fashion Industry

With 4D printing, designers could program their products to change colour or take on an entirely new pattern. Self-Assembly Printing Lab from MIT is studying potential applications of 4D technologies. One of the ideas is that clothing could change accordingly to the weather or the activity. For instance, shoes could change their shape when an individual starts running to provide them with better comfort and amortization. With 4D printing, fashion designers and studios are bringing new visions to life. For example, Nervous System, the design studio based out of Massachusetts, has created jewellery and garments with articulated joints. This allows pieces to automatically change shape once removed from the printer and placed on the model, resulting in pieces that better fit to the form of any body shape. Isn’t it amazing?

Manufacturing & Supply Chain Industry

4D printing has many potential applications throughout the organization and its potential can be relevant across the value chain. For instance, the properties of self-assembly and self-healing products can theoretically open up innovative opportunities in product design and development, create value in reductions to operations and maintenance costs, help to drive more efficient supply chains, and even eventually, lead to strategic customer engagement.

Extreme Environment

4D printing can be very useful in extreme environments such as space, as the transformable shapes of 4D printed materials would allow bridges and shelters to be built, or the possibility of self-repair when damaged by weather. In space, currently, the 3D printing process of the building causes some issues related to cost, efficiency, and energy consumption. So, instead of using 3D printed materials, 4D printed materials could be used to take advantage of their transformable shape.

Conclusion

All these potential applications seem very inspiring and promising for the future. Though we are at the very beginning of the technology of 4D printing, we have to wait to see how it will influence the future of the varied industries.