DEP Paves Way for Future of Aerodynamic Design Through Virtual Validation

Press Release, 0

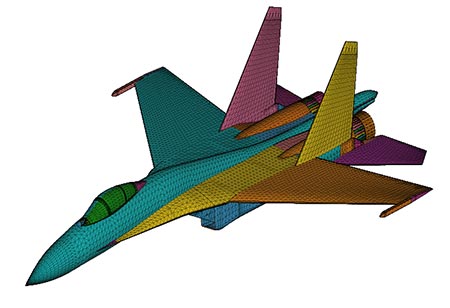

Virtual validation, a concept that has increasingly shifted to the forefront of aerospace design, plays a crucial, upfront role in ensuring safety and precision during the early stages of aircraft design. The virtual validation process provides engineers and product designers a comprehensive 3D visualization of a part or product in CAD and CAE. It establishes a simulated environment where engineers can run multiple tests to ensure validity and security of their products before physically building them.

Companies in the aerospace industry can utilize virtual validation to optimize their product development process. With the need to build prototypes for testing eliminated, engineers have the benefits of running endless tests to check safety measures, ensure strength

and endurance and operate software through CAE, all while reducing production time and costs.

Detroit Engineered Products (DEP) offers a unique platform known as MeshWorks to assist in virtual validation and optimization within the aerospace industry. MeshWorks provides an integrated CAE platform that enables users to utilize virtual validation while optimizing workflows in the industry. There is a clear increase in the volume of simulation work nowadays, as the cost of doing design changes is minimal at the concept stage. MW with its morphing and parameterization leadership, and early stage optimization enables aerospace companies to do a lot of work in the early concept stages. Through its pre-processing tools and design optimization possibilities, MW also companies complete several tasks across the concept, verification and validation, and detailed design stage. Even in the verification and validation stage, where almost all the geometric interiors and exteriors are all frozen, and the structural performances still need to be improved, MW can be very helpful.

Karthik Shankaran, Chief Innovation Officer, Detroit Engineered Products, said, “In the aerospace industry, priority of aircraft designers should be safety. We have made technological advancements; however, it is crucial to ensure safety and precision during the early stages of aircraft design. With the help of virtual validation, companies can test designs before investing in prototypes, and make sure the products are safe and reliable beforehand. This will ultimately help in saving human lives from catastrophic accidents.”

Detroit Engineered Products (DEP) offers a unique platform known as MeshWorks to assist in virtual validation and optimization within the aerospace industry. MeshWorks provides an integrated CAE platform that enables users to utilize virtual validation while optimizing workflows in the industry. There is a clear increase in the volume of simulation work nowadays, as the cost of doing design changes is minimal at the concept stage. MW with its morphing and parameterization leadership, and early stage optimization enables aerospace companies to do a lot of work in the early concept stages. Through its pre-processing tools and design optimization possibilities, MW also companies complete several tasks across the concept, verification and validation, and detailed design stage. Even in the verification and validation stage, where almost all the geometric interiors and exteriors are all frozen, and the structural performances still need to be improved, MW can be very helpful.

Karthik Shankaran, Chief Innovation Officer, Detroit Engineered Products, said, “In the aerospace industry, priority of aircraft designers should be safety. We have made technological advancements; however, it is crucial to ensure safety and precision during the early stages of aircraft design. With the help of virtual validation, companies can test designs before investing in prototypes, and make sure the products are safe and reliable beforehand. This will ultimately help in saving human lives from catastrophic accidents.”