Tata Steel's Production Capability Back to 100 Percent - CEO T. V. Narendran

CEOInsights Team, 0

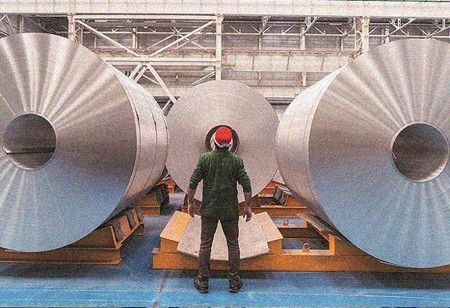

The COVID-19 outbreak in India, followed by the national lockdown, impacted the steel industry severely. It disrupted the supply chain and impacted the demand as well as production. Due to such market conditions, steel makers like Tata Steel were forced to cut down their operations by up to 50 percent in April. The players also had to turn to exports to find markets for their produce. However, with the relaxation of lockdown norms, the company ramped up its production in a phased manner.

Tata Steel’s overall India operational capacity (including Tata Steel BSL and Tata Steel Long Products) is 20.6 million tonnes per annum (MTPA). In the first quarter of 2020-21, Tata Steel India produced 2.99 million tonnes of crude steel while sales stood at 2.92 million tonnes. “We are seeing a revival in demand in Q2 led by good monsoon and the rural economy. While the auto recovery has been led by the demand for tractors and motorcycles, we are now seeing the passenger car

While the auto recovery has been led by the demand for tractors and motorcycles, we are now seeing the passenger car business pick up as well. It has also been a strong quarter for appliances

business pick up as well. It has also been a strong quarter for appliances,” asserted T. V. Narendran. He further added “The other area where Tata Steel is seeing demand is where the government is spending including the oil and gas sector, water conveyance systems and railways. Construction is still a bit slow but the monsoon quarter has traditionally been the weakest quarter for construction. In the international markets, the V-shaped recovery in China and also the country’s transition from being a net exporter of steel to a net importer has changed the demand-supply dynamics in the region”.

To counter the closure of the Indian markets in April and May, Tata Steel had ramped up exports significantly by tapping new markets and improving the supply chain capability and export constituted around 50 percent of total sales volume in April-June 2020-21. Tata Steel has reported losses in the past two quarters. During April-June of 2020-21 fiscal, the company reported a consolidated loss of Rs 4,648.13 crore. During the fourth quarter of 2019-20, the company had posted a loss of Rs 1,615.35 crore.

When asked about the markets where the company sees growth coming from, Narendran said, “The India business has always been EBITDA positive and cash positive. Hence, over the last few years, we have grown organically and inorganically in India. Given our long value chain from mining to downstream and the growth opportunities in India, we expect the India business to be one of the most profitable in the steel industry globally.”